Cement CEMEX

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the ...

WhatsApp)

WhatsApp)

Cement is a fine powder, obtained from the calcination at 1,450°C of a mix of limestone, clay, and iron ore. The product of the calcination process is clinker—the ...

Cement Process Energy Saving October, ... Cement Production Process Raw Material section Clinker ... Dust made in milling is not recovered. Factory 2

Suitable for a wide range of personnel within a cement manufacturing company including junior/middle management, technicians, production and control room staff, etc.

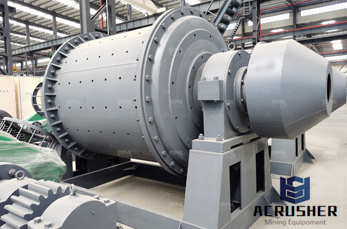

Cement Grinding mill is the main equipment used to grinding cement clinker into cement. Mail to: sales

Dry milling for cement process Crusher and grinder used for Dry cement milling is the Prehomogenize working. » Learn More. ... Cement Drying Milling Process.

View a 3D animated video of the cement production process to learn how cement is made by CEMEX.

How Cement is Made. ... Although the dry process is the most modern and popular way to manufacture cement, some kilns in the United States use a wet process.

Manufacturing Process < About Cement < Cement: Lafarge Lafarge, building better cities. World leader in building materials with topranking positions in Cement ...

The study evaluates the energy consumption of both wet and dry processes cement manufacturing plant in Nigeria. Enrgy consumption data collected for the period 2003 ...

The structure and the milling process are similar to those of the material mill. ball mill ... Cement Process Energy Saving ...

Aug 14, 2016· Video embedded· Unsubscribe from Broken line Equipment manufacturers? Now chatting: Contact Us: More ...

cement milling process_Our Company | Central Plains CementCentral Plains CementOur Company. OVER 100 YEARS OF DEDICATION AND EXCELLENCE. The .

Cement Mill,Cement Mills,Cement Ball . In the cement production line, we use cement crusher for cement crushing process, then we need cement .

Cement Milling Cement milling is usually carried out using ball mills with two or more separate chambers containing different sizes of ... As part of the grinding process

The Milling Process. The milling process has evolved from the days of grinding the wheat between two large stone wheels (although this process does still occur in a ...

Cement plant is used for cement production process in cement industry. Cement mill process is a traditional cement industry processing method in cement plant.

Conforming items are fed into the cyclone of the suspension preheater. a ball mill and a classifier were used for the cement material milling process. ... 3 Cement ...

Cement Manufacturing Process Phases. Production of cement completes after passing of raw materials from the following six phases. These .

Cement Plant Operations Handbook ... Cement Milling 69 1. ... Physical Test – 13. Process Control Analysis – 14. Cement Strength – 15.

THR Concrete Grinding''s two step process offers the fastest, most affordable trip hazard repairs, a permanent solution to problems such as raised walkways and raised ...

Modeling of Cement Milling Process Based on Long Term Industrial Data DIMITRIS TSAMATSOULIS Halyps Building Materials, Italcementi Group

12 The Milling Process 3 The Milling Process For example, very white flours would come from the early streams only, while brown flours involve using most streams.

These milling tools are suitable for all types of general junk milling, as well as for removing packers, ... Cement mills. Designed for light milling, ...

Wheat Milling Process. Background ... The modern milling process is a gradual reduction of the wheat kernels through a process of grinding and sifting.

WhatsApp)

WhatsApp)